Printed Bodies

Scientists are making leaps and bounds in developing ways to grow human body parts.

Science fiction is slowly becoming science non-fiction. Scientists are making leaps and bounds in developing ways to grow human body parts, a breakthrough that could revolutionise the way we treat, repair and think about the human body.

Last April, advanced medical research company Organovo presented a groundbreaking feat in biotechnology: the world’s first fully cellular, bio-engineered liver tissue. In layman’s terms: a man-made liver. It was small – just 20 cell layers thick – and remained alive for only five days. But what was fascinating about this tiny piece of tissue was how it had been made. It had been built by a 3D printer.

Bioprinting is a technological process that places individual cells alongside one another to form new living tissue structures. It works using a device not entirely unlike a more traditional paper printer. A cartridge is loaded with a special mixture of cells, which are slowly assembled, by a computer, into a three-dimensional shape. After that it’s down to nature. The new cells instinctively adapt to each other to complete the construction of the organ.

Bioprinting is likely to have a serious impact on how medical research is conducted. For instance, bioprinted cell models can be used to test drugs, reducing the need for animal tests. Another, and perhaps more significant advantage is that bioprinting could one day be used to grow entirely new organs to replace old or damaged ones.

Anthony Atala, director of the Wake Forest Institute for Regenerative Medicine, says incredible accuracy is a key strength of the technology. “Bioprinting technology shows much promise for tissue engineering,” he explains, “because it allows for the precise placement of cells and biomaterials to construct a tissue that is similar in configuration to our own tissue.”

However, some organs are still too complex for even the most advanced bioprinters. According to Kevin Shakesheff, head of the School of Pharmacy at the University of Nottingham, not all organs are so easy to replicate. “The most extreme example is the brain,” he says. “The function of the brain is due to billions upon billions of physical contacts between cells that are not printable. And then, of course, there’s the issue of keeping the cells and half-finished organ alive during the printing process.”

So don’t get too excited. The technology needed to print your own Frankenstein’s Monster is still a long way off.

Ears

Scientists at Cornell University managed to build a fully functioning bioprinted ear. It was made for a patient suffering from microtia, a congenital deformity in which the external part of the ear is not fully developed. At Princeton University, researchers have used a 3D printer, a petri dish and cow cells to build a pair of bionic ears that receive and transmit sound. By adding tiny particles of silver that the printer transforms into a coiled antenna, the synthetic ear is able to pick up radio signals.

Skin

A relatively simple structure with few different types of cells means skin is one of the easiest tissues to print. Anthony Atala and his team are currently developing a 3D printer that can print such tissue. He hopes this means we’ll be able to print directly on to burns and other wounds.

Bones

Bioprinting already enables us to both regenerate and fix broken bones. According to Kevin Shakesheff, a printer can create a scaffold in the shape of the bone and coat it with human stem cells capable of evolving into many different tissue types. The printed product can be implanted in the body, where the scaffold will degrade and be replaced by new bone in about three months; think of it as an internal cast.

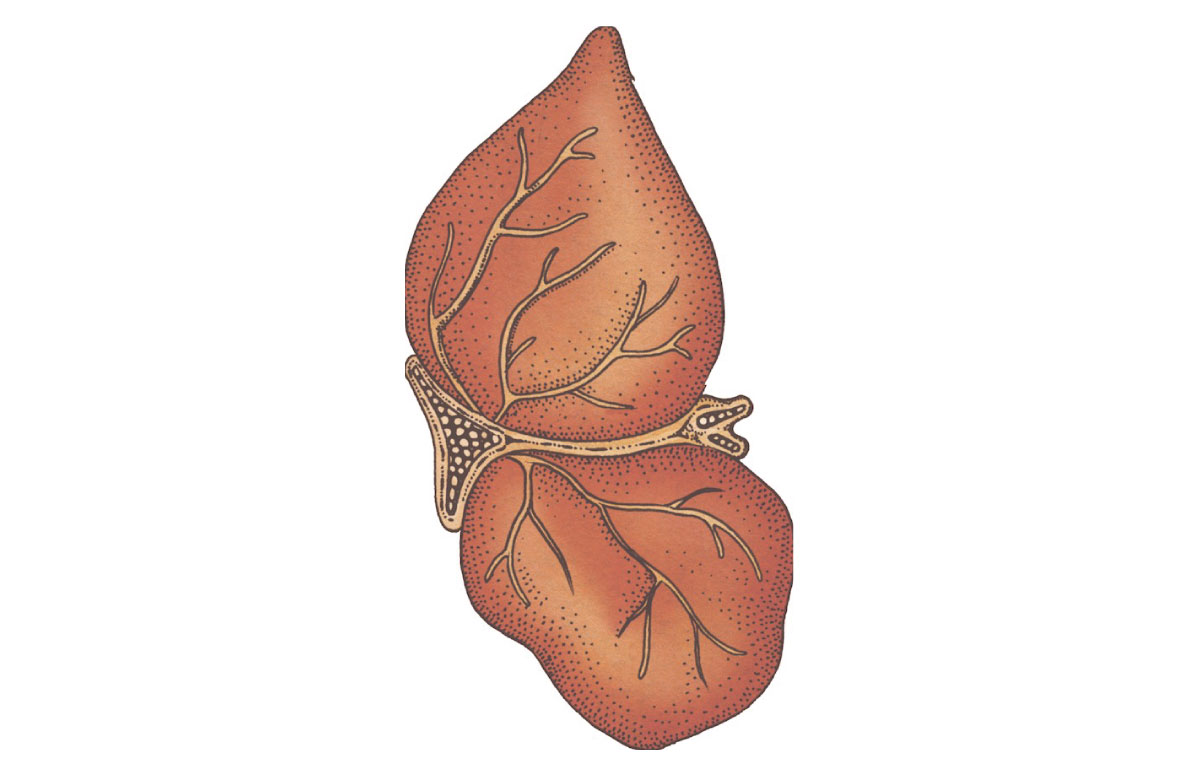

Livers

Atala and his researchers at the Wake Forest Institute have also created miniature liver structures that they plan to use to test the effects of toxins on the body, as well as potential antidotes to the effects of chemical and biological weapons.

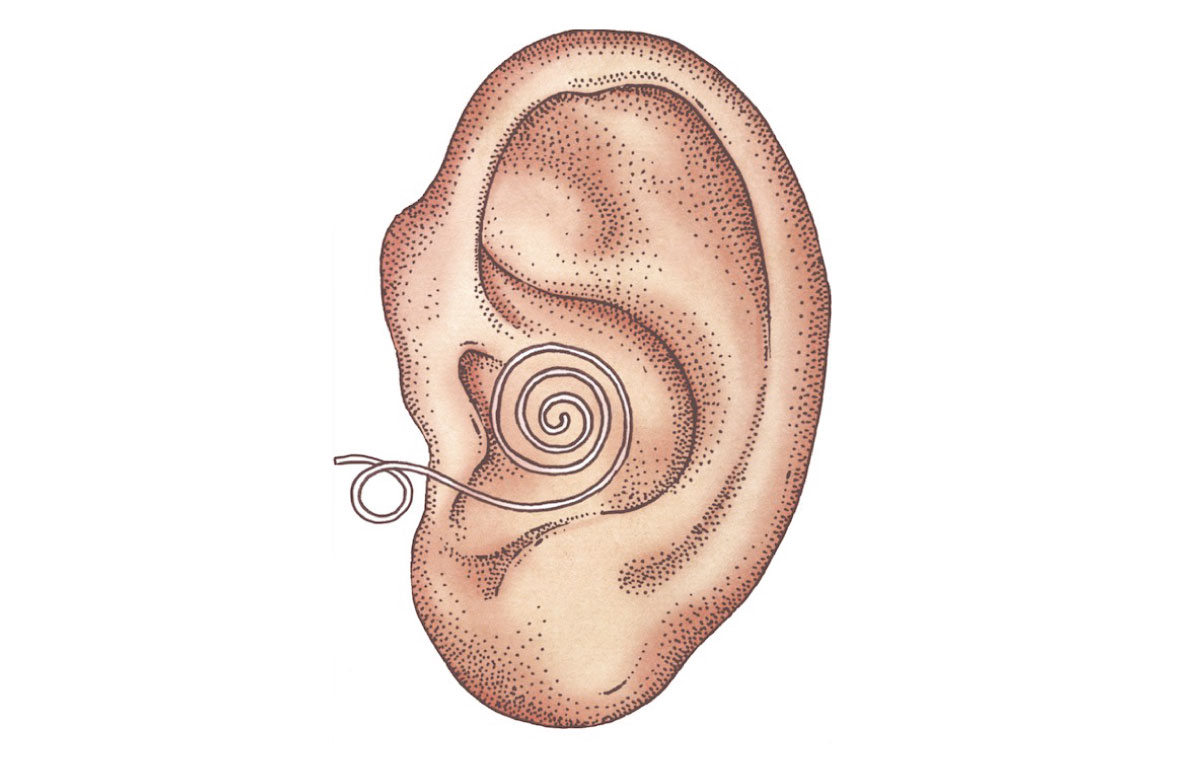

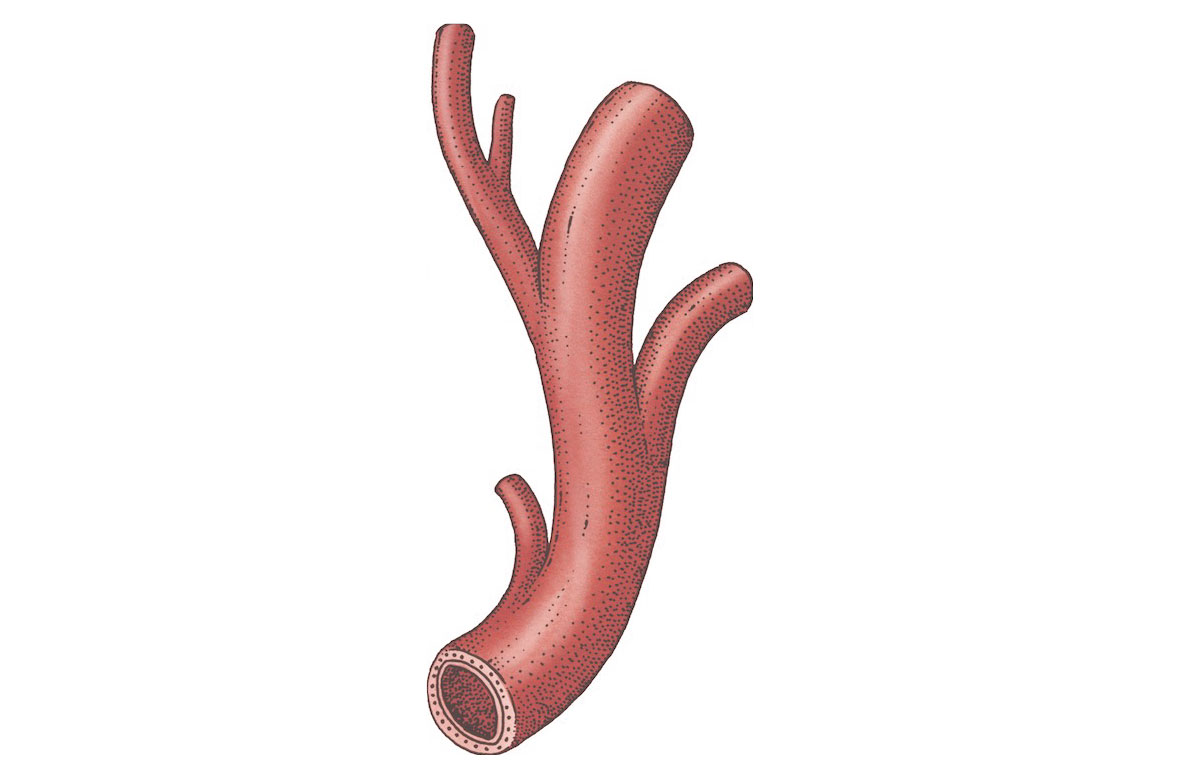

Blood Vessels

In 2012 researchers at University of Pennsylvania developed a way of artificially creating new blood vessels. The team used a customised RepRap 3D printer, and filled its cartridge with a special sugar-based solution made up of sucrose, glucose and dextran, which was used to create a blood vessel mould. This was then filled with tissue cells, before the sugar mould was washed away.

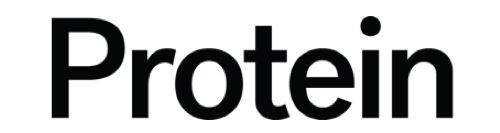

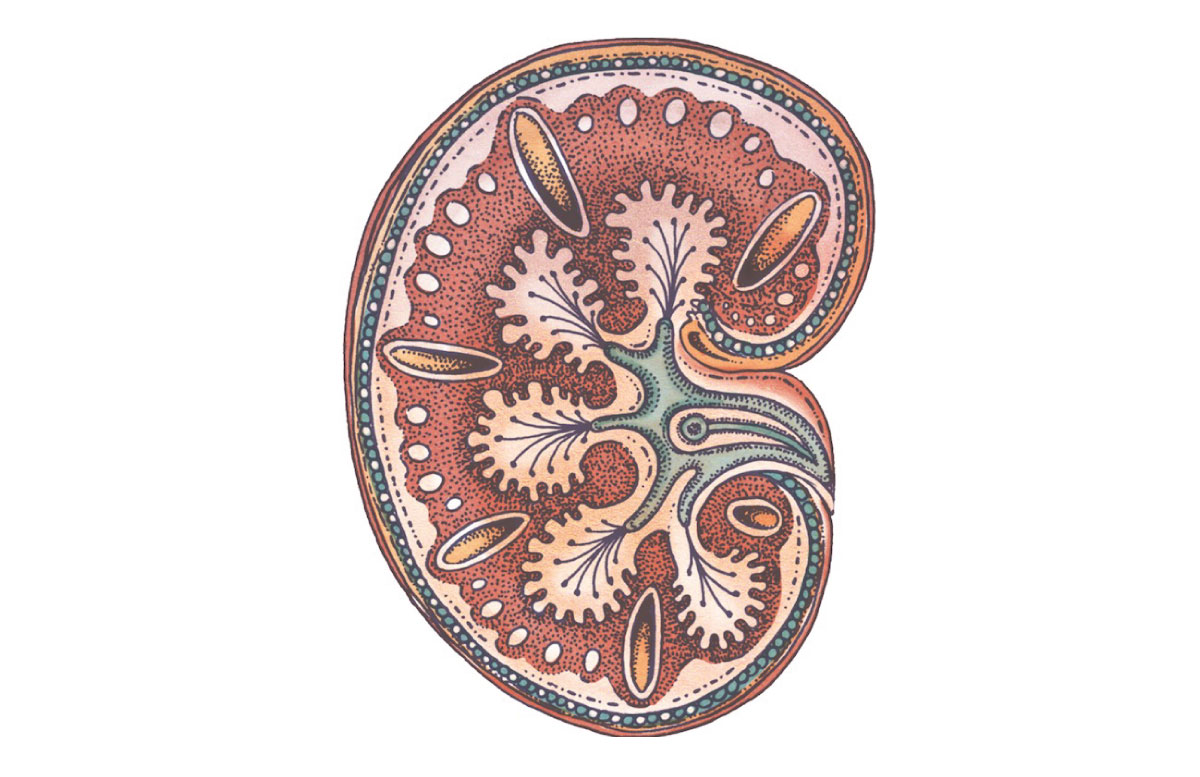

Kidney

Back in 2011, Anthony Atala amazed onlookers by bioprinting a kidney live on stage at a TED conference talk. He is now developing techniques to keep printed kidney cells alive for longer.